For those who work in the confectionery, baking, or chocolate industries, knowing how to temper chocolate is a must. The following qualities are absent from improperly tempered chocolate:

- A smooth breakage when cracked

- A shiny, polished appearance.

- The product may be kept and transported for an extended period of time without fat bloom.

Inadequate restraint in wholesale operations can result in product rejection, increased returns, brand harm, and monetary loss. Here we will discuss the best methods for tempering chocolate, whether you’re working with a small batch or in a large factory.

How Proper Chocolate Tempering Protects Product Quality

Here at Bakerdeco, a top provider of Premium chocolate ingredients and equipment, we understand the importance of cooling when providing confectionery enterprises, distributors, and manufacturers with high-quality goods. Tempering is more of a science than a cooking technique; it allows you to create moulded, dipped, or chocolate bar candies with the ideal snap, glossy sheen, and extended shelf life.

We can help you improve production efficiency, decrease waste, and raise profits. It is thanks to our deep knowledge of the bulk chocolate supply and our dedication to providing solutions to businesses.

Whether you’re a distributor looking to source clients or a factory owner looking to increase efficiency, learning the art of tempering can reduce production costs by 15% aAnd reduce mistakes.

What Does Tempering Chocolate Mean?

The process of tempering chocolate implies carefully managing the heating, cooling, and reheating of cocoa butter crystals. It is done with a focus on Type V crystals, which contribute significantly to chocolate’s structure and beauty. Tempering guarantees Predictable results on automated lines—consistent results when molding or dipping —critical from an economic standpoint.

The uniformity of products depends on the manufacturers and distributors tempering them. Because quality affects repeat business, chocolate must withstand shipping, storage, and handling without losing its allure. The beta crystals in cocoa butter are best aligned during tempering, according to chocolate experts. It makes the butter more melt-in-the-mouth and suitable for high-end desserts.

Why Temper Chocolate? Key Benefits for Industrial and Wholesale Operations

Industrial customers trust tempering as a quality control procedure.

A few vital advantages for business production are:

- Reducing waste and expenses associated with rework

- Being compatible with the equipment used to temper chocolate.

To ensure quality control in professional settings, tempering is essential.

Making Things Last Longer and More Stable:

- The good news for distributors that ship statewide is that tempered chocolate will melt less during transport due to its increased heat resistance.

- The value of manufactured items, such as enrobed nuts or moulded bars, increases when they acquire the polished appearance and feel of a sharp crack.

- Efficient utilisation of resources is essential in mass manufacturing to reduce wastage caused by flawed batches and make the most of available raw materials.

- Tempering chocolate naturally preserves its antioxidants, which makes it both health-conscious and compliant with food safety rules.

If you want your business to succeed, you need excellent wholesale chocolate, and our sustainable cocoa farms provide just what you need. Their chocolate is ideal for quick tempering.

How to Melt Chocolate Correctly Before Tempering

To temper the chocolate, it must be melted completely but not burned.

Best Practices for Industrial Melting

- Stir often to keep the temperature consistent

- Never melt near a naked flame or direct source of heat

- Always employ a regulated water bath or a jacketed melting tank.

It is fundamental not to overheat cocoa butter when creating a large batch. If you do this, re-tempering will be a real challenge, and the crystal structure will be destroyed.

What is the proper way to temper chocolate?

For industrial-scale tempering, the process is three steps.

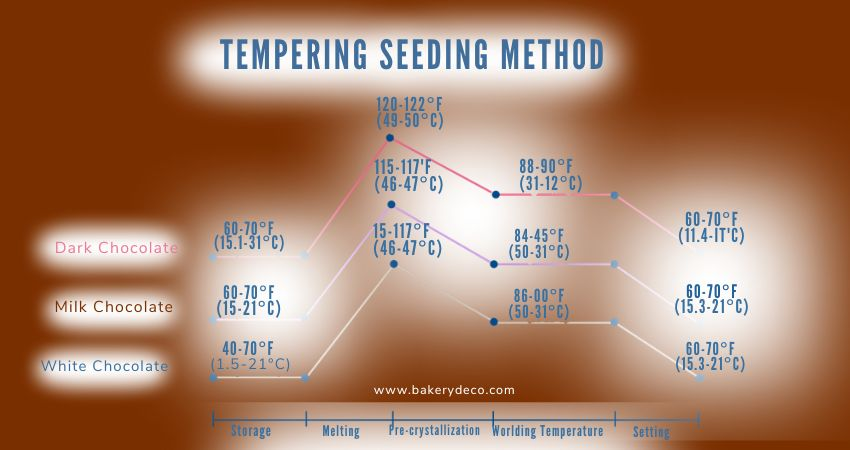

Seeding Method:

Method for Seeding in Manufacturing Facilities That Is Both Safe and Easy. Using unmelted chocolate “seeds” to temper the melt makes the seeding process ideal for both novices and large volumes.

- Cut the chocolate into small, consistent pieces to make sure it melts evenly.

- In a double boiler or industrial melter, melt two-thirds of the mixture according to the table’s recommendations.

- After the ingredients have melted and cooled, remove the pot from the heat and add the remaining 1/3 as seeds.

- Gradually bring to a working temperature if necessary.

This technology’s consistent accuracy reduces downtime for production lines. We provide bulk chocolate, so it’s easy for distributors to increase their supply.

Tempering Chocolate Temperatures Chart

Chocolate Type | Melting Temperature | Cooling Temperature | Reheat To (Working Temp) |

White Chocolate | 40–47°C | 25–26°C | 28–29°C |

Dark Chocolate | 45–50°C | 27–28°C | 31–32°C |

Milk Chocolate | 46–47°C | 26–27°C | 29–30°C |

Worldwide, several commercial kitchens and industrial facilities rely on this table to temper chocolate.

How to Temper Dark Chocolate (Factory & Wholesale Method)

Commercial uses predominate for dark chocolate because of its strong flavour.

Step-by-Step (Manual or Semi-Automated)

- Bring the dark chocolate to a temperature between 45 and 50°C.

- Use a cooling machine or a marble surface to bring the temperature down to 27 or 28 degrees Celsius.

- Gradually increase the heat to about 31 and 32 degrees Celsius, stirring occasionally.

- Keeping the temperature steady is the fourth rule of moulding or dipping.

Tempering dark chocolate, which has a cocoa concentration of 50–90%, at higher temperatures imparts its distinctive flavour.

Follow the seeding method:

After it reaches 88–90°F, lower the heat to 82–84°F. Increase the temperature to 115 to 120 degrees Fahrenheit. The recipe calls for factory-moulded bars because of their high cocoa butter content, which gives them that distinctive snap.

How to Temper Milk Chocolate for Commercial Use

Use a lower heat to avoid scorching the milk solids and achieve a creamier milk chocolate (30-45% cocoa). Milk chocolate, which contains milk-derived lipids, is extremely temperature-sensitive.

Key Considerations

- The operating temperature is around the same as dark chocolate

- To prevent graininess, the cooling rate is slower

- Stir tanks or equipment often.

Milk chocolate is commonly used for;

- a)Enrobing bars

- b)Filling chocolates

- c)Producing decorative coatings

Working at 84–86°F follows cooling to 80–82°F after melting to 105–113°F. Our milk combinations are versatile, making them a great inventory item for distributors.

How to Temper White Chocolate in Bulk Production

Due to its high sugar and milk fat content and lack of cocoa solids, white chocolate is the most challenging kind of chocolate to refine. White chocolate melts at room temperature.

Industrial Best Practices

1) Keep temperatures below 45°C

2) Use accurate thermostat settings at all times

3) Avoid moisture whenever possible.

Tempering white chocolate is a common practice before using it to coat pastries or make upscale confections, ensuring a flawless finish.

What is the easiest method of tempering chocolate?

Tabling Method: Professional Technique for High-Volume Operations

Artisanal chocolate manufacturers use this method by spreading melted chocolate over a cooled surface.

- Cook the chocolate until it reaches a full boil.

- Stir in the remaining 1/3 of the ingredients and thicken the mixture using spatulas; set aside to cool.

- Once the leftover melt has cooled to a bearable temperature, please return it to the basin and stir it in.

It is perfect for specialist tempering stations in wholesale operations, and although it does require space, it produces a superb shine.

How to Temper Chocolate Without a Thermometer (Small-Scale Option)

Even though it’s not something manufacturers should be doing, some artisan producers do it anyway:

- Cooled Chocolate does not feel icy when placed on the lips.

- The setting time is approximately 3 to 5 minutes at room temperature.

- Breaks apart with a bit of cracking noise.

Using a Chocolate Tempering Machine: Industrial Solution for Wholesale Efficiency

Chocolate tempering machines provide several potential advantages for businesses and wholesalers. These include;

- An automated means to control the temperature

- Continuous tempering for high production

III. Reduced labour costs

- Consistent batch quality.

Ideal For:

- Producers to export

- Wholesalers of confections

- Facilities for cooperative chocolate manufacturing

Investing in machinery may boost your ROI and expand your business.

How to Temper Chocolate for Dipping (Professional Applications)

- a)If you want to dip anything, it might be fruits, cookies, wafers, or even caramel centres:

- b)For the perfect Chocolate, it should have the perfect texture—soft and chewy.

- c)Coatings that have been tempered correctly set rapidly and evenly. –

- d)Be careful not to leave streaks or use a light hand to finish.

- e)It is the go-to strategy for many private-label manufacturers and service providers.

Use enrobers to improve the performance of industrial dipping lines. That is why we stock dipping-grade Chocolate in our wholesale inventory.

How to Melt Chocolate: Fundamentals Before Tempering

Tempering is useless if the melting process fails. While stirring often, heat in a microwave or double boiler over low heat for brief intervals on high. Seizures are less likely to occur if you avoid hot or watery environments. Industrial melters can handle large materials safely so that manufacturers can rest easy.

Commercial Considerations: Scaling Tempering for Factories and Distributors

For business transactions, we calibrate scales using specific equipment. Continuous operation and adherence to FDA regulations are achieved through PLC controllers on tempering equipment. Distributors: To help you focus on logistics, you may let us handle chocolate tempering.

Partner with Bakery Deco for Superior Chocolate Tempering Solutions

If you’re selling your product to other businesses, tempering chocolate might be the key to your success. You may save time and money by working with us as your retail partner; we can provide high-quality chocolate, tools, and advice. Contact us soon for samples and wholesale pricing; we can achieve great things together.